Call Us08045803090

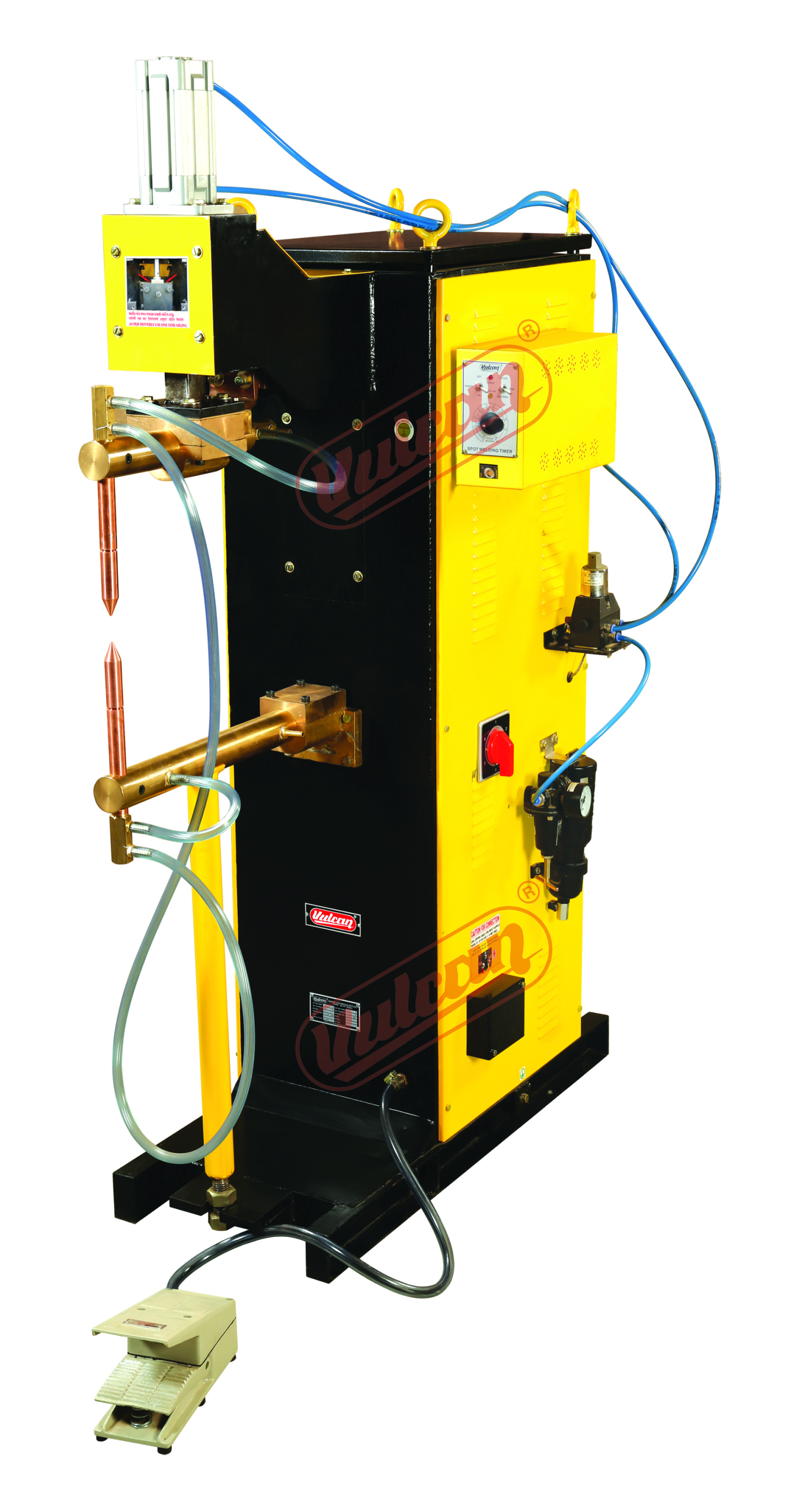

Spot Welding Machine

110000.00 INR/Unit

Product Details:

- Composition Electrodes: Copper Alloy, Body: Steel

- Application Joining Sheet Metals, Automotive Assembly, Industrial Fabrication

- Operating Voltage 415 V AC

- Operating Temperature 0C to 50C

- Usage Resistance Welding Machine

- Material High Quality Steel

- Diameter Electrode Diameter: 10 mm

- Click to View more

X

Spot Welding Machine Price And Quantity

- 1 Unit

- 110000.00 INR/Unit

- 12 kVA

- 350 mm

- Copper Alloy

- 50 Hz

- Pneumatic Pressure Adjustable 2 6 Bar

- Digital Timer Control

- Approx 120 kg

- 0.1 - 3 sec Adjustable

- Water Cooled Electrodes

- Up to 3 mm

Spot Welding Machine Product Specifications

- Joining Sheet Metals, Automotive Assembly, Industrial Fabrication

- Pneumatic Spot Welding Machine

- Resistance Welding Machine

- Electrodes: Copper Alloy, Body: Steel

- Copper Coated Electrodes

- High Quality Steel

- 0C to 50C

- 415 V AC

- Electrode Diameter: 10 mm

- Yellow

- Electrode Melting Point: 1500C

- 12 kVA

- 350 mm

- Copper Alloy

- 50 Hz

- Pneumatic Pressure Adjustable 2 6 Bar

- Digital Timer Control

- Approx 120 kg

- 0.1 - 3 sec Adjustable

- Water Cooled Electrodes

- Up to 3 mm

Spot Welding Machine Trade Information

- 20 Unit Per Day

- 1 Week

Product Description

Scope And Applications

Vulcan Pneumatic Operated Spot Welding Machines Are Offered In 20, 30, 50, 75 & 100 Kva Models. All Machines Are Made Of Steel Fabricated Rigid Structures Eliminate The Minutest Spot Deflection. Pneumatic Spot Welders Are Designed For High Speed Production Jobs Meet Vast Needs Of Metal Fabrication Industries Including Sheet Metal Components, Cross Wire Welding, Kitchenware, Electro Brazing, Resistance Heating Etc.

Salient Features

- Transformer :Low Leakage (High Linkage) Design, Proper Cooling And Insulation Including Winding Varnishing By Vacuum Pressurized Impregnating System To Enhance Reliability And Service Life.

- Time & Current Control : Current Setting From Min. To Max. Can Done By 6 Position, Off Load Tap Changing Switch & Micro Processor Based Synchronous Controller With 25 Different Programs Of Setting Is Incorporated With These Machines In Order To Obtain Consistent And Accurate Weld Results Of The Jobs

- Electrodes :One Pair Of 2 Straight Electrodes Made From Hardened Copper-Alloy Is Supplied With The Equipment. Other Types Of Spare Electrodes Can Be Supplied On Specific Orders.

- Cooling: Electrodes And Arms Are Provided With Water Cooling Arrangement With Hose Connections. Main Transformer Natural Air Cooled Or Water Cooled.

Digital Precision Control

Equipped with a digital timer control system, this spot welding machine allows for precise setting of welding times from 0.1 to 3 seconds. This enhances accuracy and repeatability in industrial fabrication processes, reducing material waste and improving output quality.

Efficient Cooling Mechanism

To ensure stable performance even during continuous operation, the machine uses water-cooled copper alloy electrodes, which efficiently dissipate heat. This cooling system helps maintain electrode lifespan and consistent weld quality.

Versatile Industrial Application

Ideal for automotive assembly, metal sheet fabrication, and general industrial uses, this machine is engineered for demanding environments. Its sturdy steel body and adjustable pneumatic pressure make it adaptable for a range of sheet metal joining tasks.

FAQs of Spot Welding Machine:

Q: How does the digital timer control enhance the spot welding process?

A: The digital timer control allows operators to set the welding time precisely between 0.1 and 3 seconds, ensuring consistent weld quality and minimizing the risk of overheating or weak joints.Q: What is the maximum thickness of sheet metal this spot welding machine can join?

A: This spot welding machine can reliably weld sheet metals up to 3 mm thick, making it suitable for various automotive and industrial fabrication applications.Q: When should the water cooling system for the electrodes be activated?

A: The water cooling system should be running whenever the machine is in operation, as it helps prevent the copper alloy electrodes from overheating and extends their service life during high-duty cycles.Q: Where can this spot welding machine be effectively used?

A: This welding machine is ideal for use in automotive assembly lines, sheet metal workshops, industrial fabrication units, and manufacturing plants across India and globally.Q: What is the process of adjusting welding pressure on this machine?

A: Welding pressure can be adjusted pneumatically between 2 and 6 bar, allowing the operator to tailor force based on the thickness and type of material being welded.Q: How does the use of copper alloy and water cooled electrodes benefit the welding operation?

A: Copper alloy electrodes with water cooling provide excellent electrical conductivity and resist deformation at high temperatures, ensuring strong, consistent welds and reducing electrode wear.Q: What are the main benefits of using this spot welding machine for industrial applications?

A: Key benefits include high efficiency, reliable weld quality, adaptability to multiple material types, reduced downtime due to efficient cooling, and precise process control, contributing to increased productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Spot Welder Machines' category

|

CANARY ELECTRICALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |